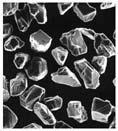

Diamond submicro, micro and grinding powders

LLC STILLMEL produces and supplies synthetic diamond powders according to the requirements of GOST, IDA Std 1985, ANSI, DIN and other international standards for the certification of diamond powders. All the products are certified, and the the price - quality - stability ratio is an optimum factor of cooperation with our company.

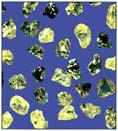

Diamond micropowders

Diamond micropowders are produced with increased (ACH) and normal (ACM) abrasive ability.

- 29 grain sizes of diamond powders are produced commercially;

- impurities make no more than 0.5% (GOST – 2.0%);

- the base grain is not less than 80% (GOST – 70%);

- the coarse and fine grains are within the limits set by the certain standards;

- the increased abrasive ability of diamond during a grain ovalization;

- the diamond powder is produced according to the requirements of the most common western standards.

Intended use: for the manufacture of a diamond tool with various bonds, including galvanic, and also for the manufacture of diamond pastes and suspensions, and for the use as loose abrasive.

Field of application: sharpening of hard-carbide tipped tools; cutting, grinding, finishing and polishing of parts made of tempered steels, hard alloys, ceramics, glass, sapphire, corundum, semiconductor materials, ornamental and precious stones, other non-metallic materials, and polished finish of stone.

Diamond micro powders with granularity 60/40 - 14/10 are covered with nickel coating (55%, 60%, and 65% by weight) for the improvement of operability of polishing diamond rings and diamond pastes.

The indication of granularity of diamond micro powders for various standards:

| F.E.P.A. Standard |

US Standard, grain number |

US Standard, MESH |

Grain size micrometer |

GOST micrometer |

|---|---|---|---|---|

| 1/4 | 100.000 | 0-1/2 | 0,3/0 | |

| 1/2 | 60.000 | 0-1 | 0,5/0 | |

| M 1.0 | 1 | 14.000 | 0-2 | 1/0 |

| M 1.6 | 2 | 12.000 | 1-3 | 2/1 |

| M 2.5 | 3 | 8.000 | 2-4 | 3/2 |

| M 4.0 | 4 | 5.000 | 2-6 | 5/3 |

| 5 | 4.000 | 4-6 | ||

| M 6.3 | 6 | 3.000 | 4-8 | 7/5 |

| M 10 | 8 10 |

2.000 1.700 |

6-10 8-12 |

10/5 10/7 |

| 12 | 1.500 | 8-16 | 14/10 | |

| M 16 | 1517 | 1.200 1.100 | 10-20 12-22 | 20/14 |

| M 25 | 20 | 1.000 | 15-25 | 28/20 |

| 25 | 800 | 20-30 | ||

| 30 | 650 | 22-36 | ||

| M 40 | 35 | 550 | 30-40 | 40/28 |

| 45 50 |

520 500 |

36-54 40-60 |

60/40 | |

| 60 100 |

325/400 270/325 |

54-80 80-120 |

Diamond grinding powders AC4, AC6

- from 8 to 14 grain sizes of diamond grinding powders produced commercially;

- impurities and non-combustible residue in diamond powders are no more than 1.2-1.5%;

- grain composition of diamond powders are according to GOST and US mesh.

Intended use: production of diamond tools with organic and metal bonds.

Field of application: АС4 (the diamond powder in the form of aggregates and intergrown pieces) - the production of the diamond tools with organic bonds for processing of solid alloys, ceramics, non-metallic and other brittle materials. АС6 (the diamond grinding powder presented by separate crystals with the developed surface, aggregates and intergrown pieces) - the production of tools with metal bonds used for coarse finishing of hard alloys and various non-metallic materials. Diamond grinding powders are covered with nickel coating (55 - 56% of Ni by weight) for the improvement of operability of polishing diamond rings.

The indication of granularity of diamond grinding powders for various standards:

| F.E.P.A. Standard |

US Standard, MESH |

Grain size micrometer |

GOST 9206-80, micrometer |

|---|---|---|---|

| D251 | 60/70 | 250/212 | 250/200 |

| D213 | 70/80 | 212/180 | 200/160 |

| D181 | 80/100 | 180/150 | |

| D151 | 100/120 | 150/125 | 160/125 |

| D126 | 120/140 | 125/106 | 125/100 |

| D107 | 140/170 | 106/90 | 100/80 |

| D91 | 170/200 | 90/75 | |

| D76 | 200/230 | 75/63 | 80/63 |

| D64 | 230/270 | 63/53 | 63/50 |

| D54 | 270/325 | 53/45 | 50/40 |

| D46 | 325/400 | 45/38 |

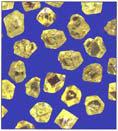

Diamond grinding powders AC15...AC100

- any sizes and grades from AC15 to AC100;

- structural characteristics and grain size composition are according to GOST;

- the whole range of diamond powders are available in the warehouse of the company;

- all diamond powders are certified by Gosstandart of the Russian Federation;

- all diamond powders are made from Diagloss raw materials of Element Six production produced on the iron-nickel catalyst;

- high thermal resistance and strongly-pronounced non-magnetic properties of diamond powders;

Intended use: production of diamond tools with metal and galvanic bonds.

Field of application: processing, cutting and drilling of various non-metallic materials, ceramics, glass, porcelain, sapphire; stone grinding and cutting

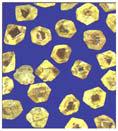

Diamond polycrystalline powders

produced by means of the sintering of diamond micro powders with subsequent grinding

Intended use: production of mono-crystalline diamond tools, single-point diamonds, boring tools, diamond tools for building industry, concrete and stone grinding.

The basic grades: АРС3, АРС4, grain range up to 2000/1600

Our prices for diamond powders in accordance with GOST 9206-80

Postscriptum from STILLMEL

Beyond any doubt, it is possible to find and buy diamond powders a little cheaper than in our company. But will you be sure that it is a qualitative product that you will be able to check? Will you be sure that this powder is not stolen and you will be able to make a complaint to a yet another intermediary later on? Will you be sure that you saved money when such cheap powder has despairingly spoiled the processed surface of the material the cost of which exceeds the cost of "cheap" powder many times?

Ponder over the issue (a cheapskate pays even not twice...); go and purchase a small amount of "such diamond powder" and bring it to us for testing that we will perform at your presence and you will be convinced once again: the good thing will not be cheap... OUR ASSESSMENT IS OBJECTIVE and it is supported with the accurate analysis performed on the state-of-the-art equipment manufactured by the leading western companies.